-

Products

-

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

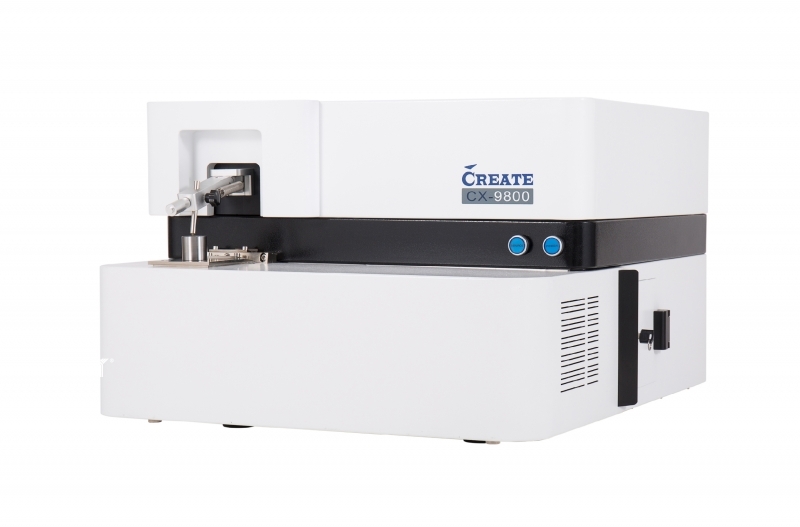

An alloy is a mixture of metal melted with metal (or non-metal) with excellent metal characteristics. Compared with its single metal (or non-metal) component, an alloy features high hardness, low melting point, low density, and strong resistance to corrosion and other advantages, which can be better used in industrial tension, bending, pressure-bearing, welding, etc. However, the characteristic of an alloy will be varied with its different element contents. The photoelectric direct-reading spectrograph is a high-performance metal composition analyzer, which features high speed of analysis, easy use, high reliability and low maintenance cost, and can be used for analyzing the elements such as Fe, Cu, Zn, Ni, Ti , Mg, Co, Zr, Si, Mn in matrix.

As a Chinese icon in the automotive air conditioner industry, Colin always practices its business management philosophy of “Custom Focus”, of which evaluation criteria of products and services are subject to the customers’ high appreciation, and spares no effort in technical innovation, test and detection, and quality assurance. We have a dedicated chemical and physical laboratory, which are equipped with a high-end photoelectric direct-reading spectrograph to analyze the element contents in the metal cores of air conditioners and the metal connecting pipes. They can fully demonstrate our philosophy of insisting on customer orientation and pursuing value creation, and represent their necessities.

The operating principle of the spectrum analyzer is described briefly as follows: The excitation table electrode of the spectrum analyzer and the metal sample to be tested generate electrical spark driven by a light source module. The high temperature caused by the electrical spark heats the atoms in the metal sample to an excited state, and, when the atoms are restored to the ground state from the excited state, they emit light with characteristic spectral line, which is introduced into the light chamber of the equipment for spectroscopy and for determining the contents of elements by the intensity of the characteristic spectral lines.

CREATE CX-9800 spectrograph used in Colin Air Conditioner chemical and physical laboratory

The chemical and physical laboratory of the Colin Air Conditioner Test Center focuses on testing of raw material compositions, metallographic structure, plastic deformation of parts and components, mechanical properties, face plates and clutches service life. In addition to the spectrum analyzer, it is also equipped with testing machine of button/key service life, microcomputer-controlled Erichsen film distensibility meter, torque tester, metallographic microscope, Vickers hardness tester, etc. The Test Center concentrates on test and trial production and engages in design, R&D, quality control, and collaboration with suppliers. It has nearly 200 sets of various high-end test and detection equipment for testing the automobile A/C key parts and components and complete air conditioners and is able to perform the analysis, evaluation and structure measurement, and test the performance, safety, durability, noise, vibration, EMC, etc. of automobile air conditioners.

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram