-

Products

-

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

Minibus Air Conditioner 1.0

Started in 2008, it adopts a top-mounted split structure design, which requires high installation technology and weighs about 147kg;

Minibus Air Conditioner 2.0

Started in 2010, it adopts a top-mounted split structure design, which has high installation process requirements. It follows the first-generation lightweight feature and weighs about 136kg. It develops and applies high-performance heat exchange technology. The cooling weight is improved compared to the first-generation products, and the refrigerant charge is The injection volume is reduced by 30%;

Minibus Air Conditioner 3.0

Started in 2017, it adopts a top-mounted overall structure design to make the air conditioner easier to install. It adopts a second-generation integrated lightweight design and weighs about 134kg. It develops and applies high-performance heat exchange technology and reduces the refrigerant charge by 30%;

Minibus Air Conditioner 4.0

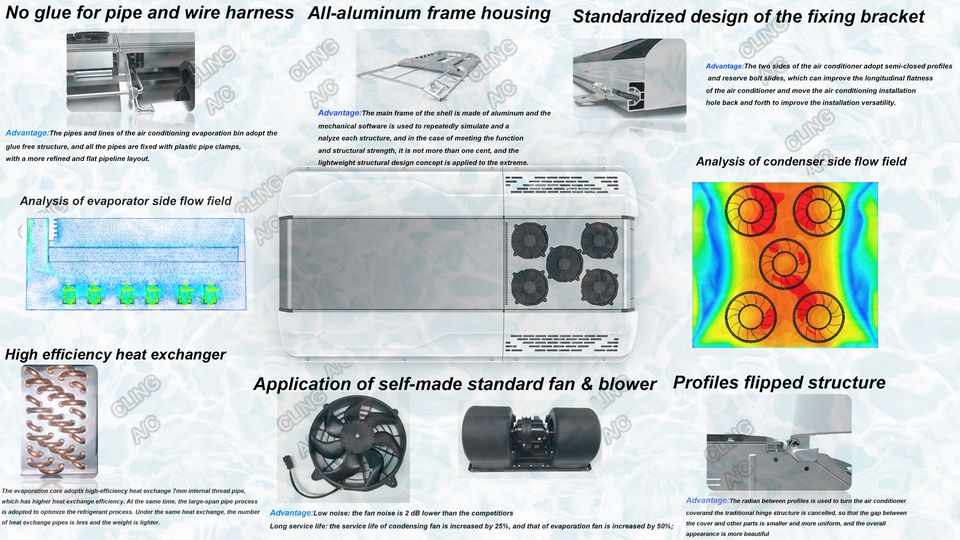

Starting in 2021, Refinement—the pipeline adopts a new fixing method, the layout is regular, the steam-cooling integrated cover, the hidden bolts are supplemented by the new concave and convex surface shape, the whole machine has a fashionable and comfortable appearance, with the best visual effect.

The third generation of integrated lightweight design, the air conditioner weighs about 110kg, and the package size is 20% smaller than the previous generation product. The compact body, all-aluminum structure combined with high-strength and lightweight RTM composite material creates a lightweight milestone.

High performance—The cooling capacity reaches 13- 16kW, far exceeding the existing products of the same platform, new subversive structural design, still strong and reliable under 4g acceleration vibration conditions.

Streamlined layout, optimizing the air conditioning wind field/flow field, reducing process losses, and improving efficiency.

Easy to maintain—Compact and streamlined structure. The fixed points of each component are convenient for installation and disassembly. The glue-free structure is used to pass the coil, which facilitates pipeline maintenance while ensuring sealing performance and aesthetics. The condensing fan adopts a quick-release structure, making maintenance more convenient.

Get A Free Quote!

x

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram