-

Products

-

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

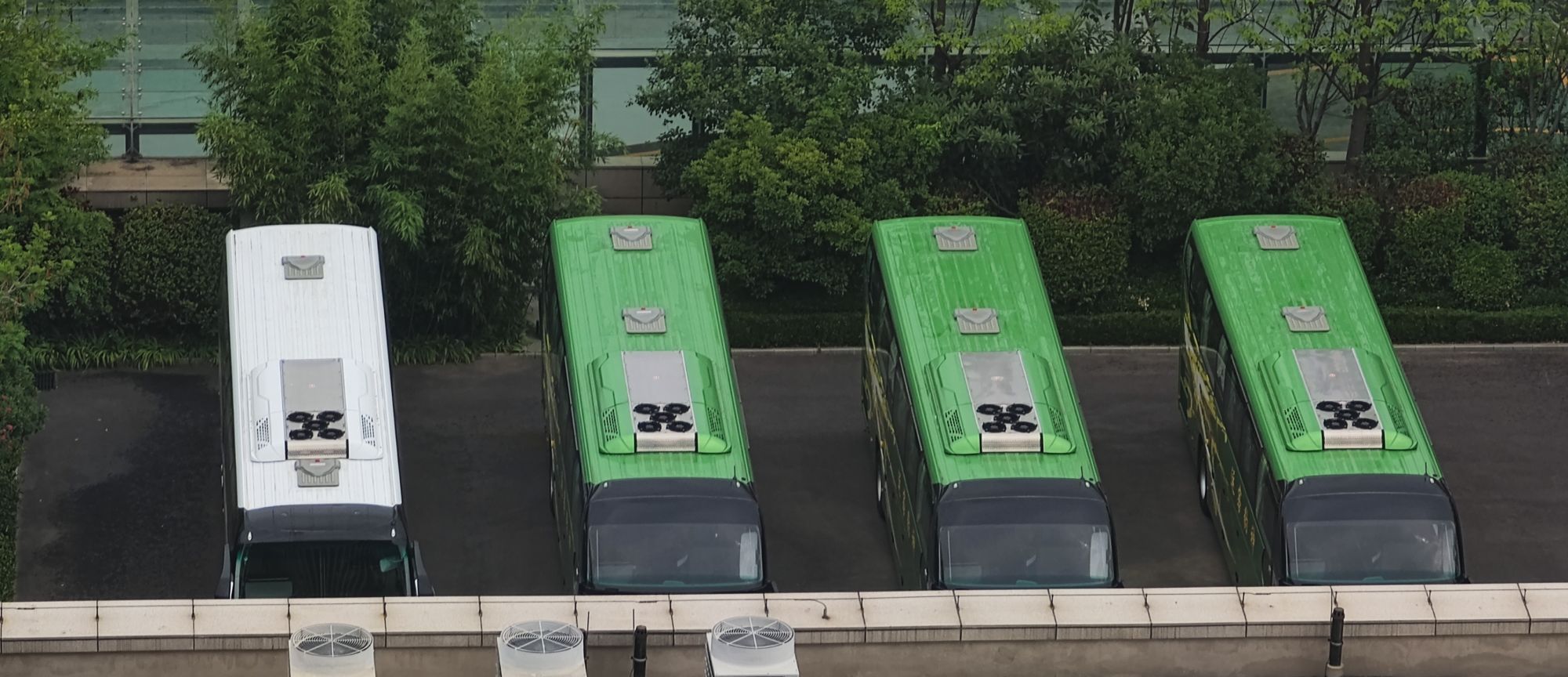

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

Thermal Management System Development History

1. Independent Battery Cooling

The independent battery thermal management unit operates according to BMS commands, divided into driving heating, charging heating, and cooling, with both forced cooling and natural cooling capabilities. The BMS transmits the operating mode and target water temperature to the water cooling unit, which then operates autonomously according to the BMS commands. The unit's flexible layout (frame and chassis) allows for application in a variety of new energy heavy-duty and light-duty trucks, construction machinery, and other applications.

.png)

.png)

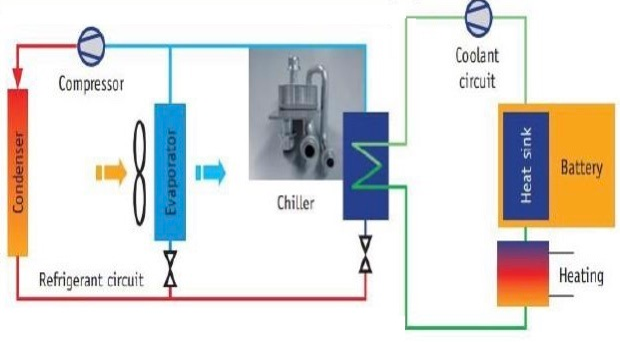

2. Cabin Air Conditioning + Battery Cooling

Currently, this primarily integrates the functions of the cabin air conditioning and liquid-cooled battery thermal management system. The condenser and motor radiator share a cooling fan, achieving integrated thermal management for the entire vehicle. The air conditioning and battery thermal management systems share components such as the compressor and condenser. Two evaporation systems are used for cabin air conditioning and power battery temperature control, respectively. The battery side utilizes a liquid cooling mode with secondary heat exchange.

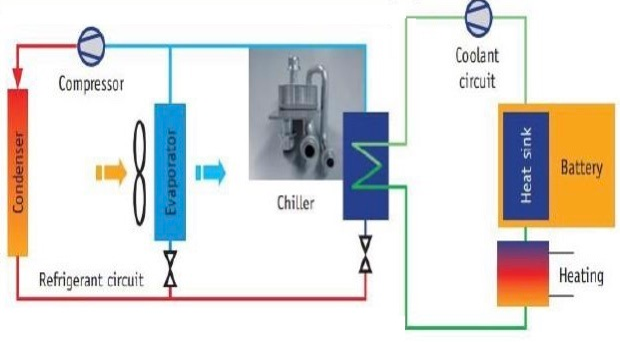

3. Integrated Thermal Management for Cabin Air Conditioning + Battery Cooling + Motor Cooling

Currently, integrated thermal management solutions all utilize a distributed layout. These solutions provide an integrated solution for motor cooling, cabin air conditioning, and battery thermal management. This system utilizes heat from the electric drive through a heat pump system for winter cab heating. This effectively reduces PTC usage, reduces vehicle energy consumption, and improves heating efficiency. The cab air conditioning and battery cooling share a common cooling fan, reducing system components and improving system reliability and integration. The integrated thermal management system has four operating modes:

1) Cabin cooling: compressor - off-board heat exchanger - solenoid valve - thermal expansion valve - HVAC assembly cooling core - gas-liquid separator - compressor;

2) Battery cooling: compressor - off-board heat exchanger - electronic expansion valve - plate heat exchanger - gas-liquid separator - compressor;

3) Cabin heating: Activate the water PTC, allowing hot water to flow through the AC unit's heating core to heat the cabin;

4) Combined Cooling: Compressor - External Heat Exchanger - Electronic Expansion Valve - Plate Heat Exchanger - Gas-Liquid Separator - Compressor

PRE: What is the Heat Pump System

NEXT:Back To List

Get A Free Quote!

x

.png)

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram