-

Products

-

Engine Bus Air Conditioner

Engine Bus Air Conditioner

-

E-Bus Air Conditioner

E-Bus Air Conditioner

-

BTM System

BTM System

-

Refrigeration Unit

Refrigeration Unit

-

Defroster

Defroster

-

Integrated Thermal Management System & Heat Pump Product

Integrated Thermal Management System & Heat Pump Product

-

Accessory

Accessory

.jpg)

-

Engine Bus Air Conditioner

- About Us

- Support

- Contact Us

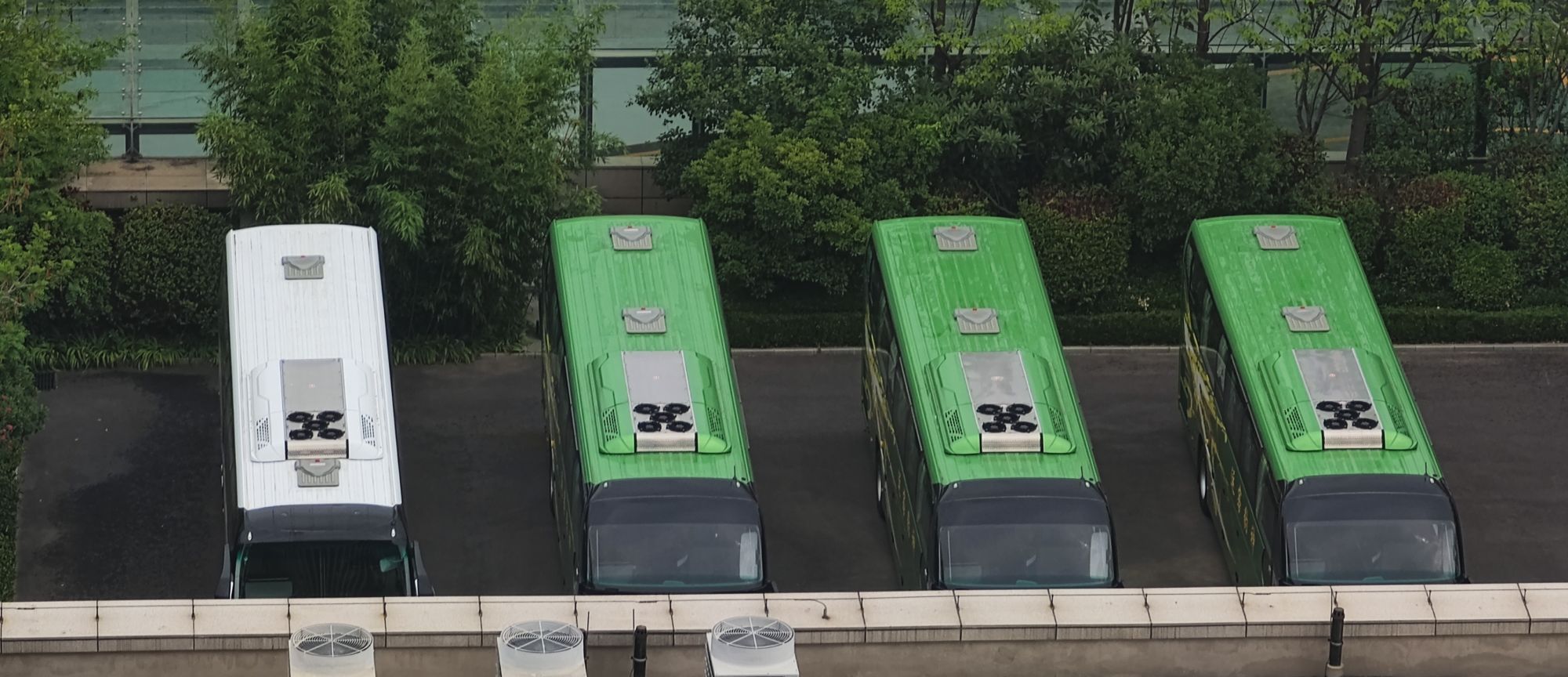

What's the Heat Pump System?

Today we'll provide a comprehensive introduction to heat pump systems for electric buses. Heat pump systems are related to an electric bus's range, passenger comfort, and operating costs.

Today we'll provide a comprehensive introduction to heat pump systems for electric buses. Heat pump systems are related to an electric bus's range, passenger comfort, and operating costs.

1. Core Concept: What is a Heat Pump System?

You can think of it as an air conditioner that works in reverse.

Conventional air conditioning (summer): It absorbs heat from the vehicle interior (the evaporator absorbs heat) and then releases it to the outside (the condenser releases heat), thereby cooling the interior.

Conventional PTC heating (winter): Like a large hair dryer or heating rod, it directly draws power from the battery to generate heat for heating the interior. This method is highly inefficient and consumes a significant amount of electricity.

Heat pump systems (winter): They absorb heat from the ambient air outside (even cold air contains heat) and, through a compressor and refrigerant cycle, "pump" this heat into the vehicle interior, heating the cabin and acting as a "heat transporter."

2. Why are heat pump systems particularly important for electric buses?

This is due to the unique characteristics of electric buses, with the core conflict revolving around range.

The energy efficiency issue of traditional PTC heaters: In winter, the warm air in fuel-powered buses comes from engine waste heat, making it virtually "free."

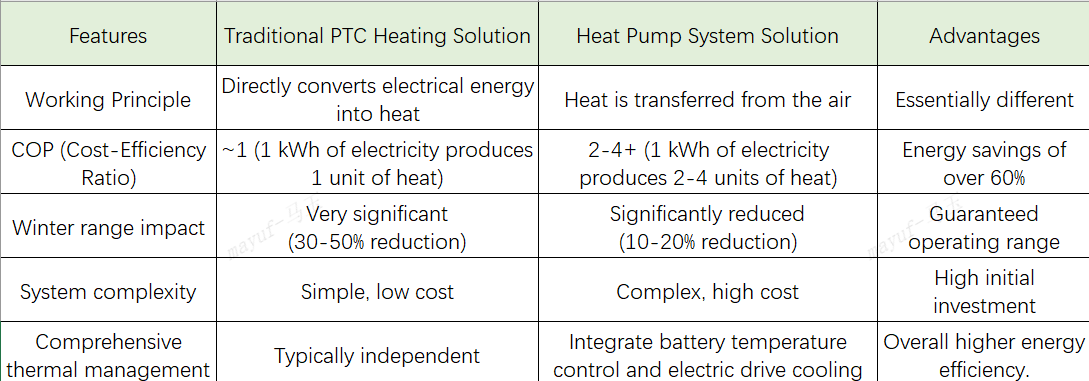

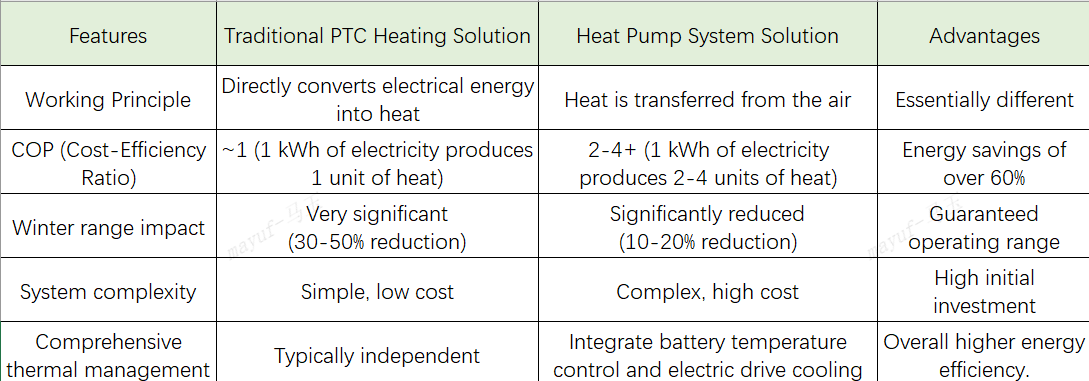

But electric buses no engines, eliminating this heat source. Early electric buses commonly used PTC heaters, whose coefficient of performance (COP) was typically close to 1: consuming one unit of electricity for a maximum of one unit of heat. Winter heating is a significant energy drain and may reduce an electric bus's range by 30%-50%. This is devastating for buses operating long, fixed routes, potentially forcing them to recharge, severely impacting operational efficiency.

The significant advantage of heat pump systems: Heat pumps don't directly generate heat; they transport it. Their COP can typically reach 2-4 or even higher. This means that for every unit of electricity consumed, two to four units of heat can be "transported." The benefit is a significant improvement in winter driving range. Using a heat pump system can save up to 50%-70% in heating energy compared to PTC heating, significantly reducing range degradation, ensuring vehicle mileage and reliability, and ultimately lowering operating costs. Modern heat pump systems typically simultaneously manage passenger compartment cooling and heating, battery pack cooling and heating (batteries perform best and have the longest life at optimal temperatures), and electric drive system heat dissipation, forming an integrated, intelligent, and efficient thermal management system.

The significant advantage of heat pump systems: Heat pumps don't directly generate heat; they transport it. Their COP can typically reach 2-4 or even higher. This means that for every unit of electricity consumed, two to four units of heat can be "transported." The benefit is a significant improvement in winter driving range. Using a heat pump system can save up to 50%-70% in heating energy compared to PTC heating, significantly reducing range degradation, ensuring vehicle mileage and reliability, and ultimately lowering operating costs. Modern heat pump systems typically simultaneously manage passenger compartment cooling and heating, battery pack cooling and heating (batteries perform best and have the longest life at optimal temperatures), and electric drive system heat dissipation, forming an integrated, intelligent, and efficient thermal management system.

3. How Does a Heat Pump System Work?

At its core, it is based on the refrigerant's compression-condensation-expansion-evaporation cycle. A four-way reversing valve changes the refrigerant's flow direction, switching between cooling and heating modes.

Winter Heating Mode:

External Heat Exchanger (acting as the evaporator): Liquid refrigerant flows through this heat exchanger, absorbing heat from the ambient air outside the vehicle (even at 0°C, the air still contains heat), and evaporates into a low-temperature, low-pressure gas. Compressor: Consumes electricity to compress low-temperature, low-pressure gas into high-temperature, high-pressure gas.

In-vehicle heat exchanger (acting as a condenser): High-temperature, high-pressure refrigerant gas flows through this heat exchanger, releasing heat to the air inside the vehicle. It condenses into a high-pressure liquid, which is then heated and blown into the vehicle cabin by the fan.

Expansion valve: The high-pressure liquid is throttled by the expansion valve, becoming a low-temperature, low-pressure liquid again, returning to the external heat exchanger to begin the next cycle.

Summer Cooling Mode:

The process is identical to that of a conventional air conditioner. The four-way valve switches direction, turning the internal heat exchanger into an evaporator (heat absorption) and the external heat exchanger into a condenser (heat release).

Complex Operating Conditions and Challenges:

In extremely cold weather (e.g., below -15°C), the ambient air contains less heat, and the heat pump's efficiency decreases. In these cases, the system may need to activate an auxiliary PTC heater as a supplement, or employ more advanced technologies (such as air injection) to improve performance at low temperatures. The external heat exchanger is prone to frost in low-temperature, high-humidity environments. Frost builds up on the surface, hindering heat absorption. Therefore, the system requires regular defrost cycles (briefly switching to cooling mode to allow hot refrigerant to flow through the external heat exchanger to melt the frost). This cycle can temporarily affect heating performance.

4. Summary: The Significance of Heat Pump Systems for Electric Buses

The heat pump system is no longer an "optional feature" for electric buses; it is a key technology and an inevitable trend towards higher efficiency and longer driving range. Its superior "heat transfer" technology cleverly addresses the core pain point of high winter heating energy consumption in electric buses, making it a key component that ensures stable and efficient operation in all weather and seasons.

(2).png)

(2).png)

Get A Free Quote!

x

Youtube

Youtube

Facebook

Facebook

Linkedin

Linkedin

Instagram

Instagram